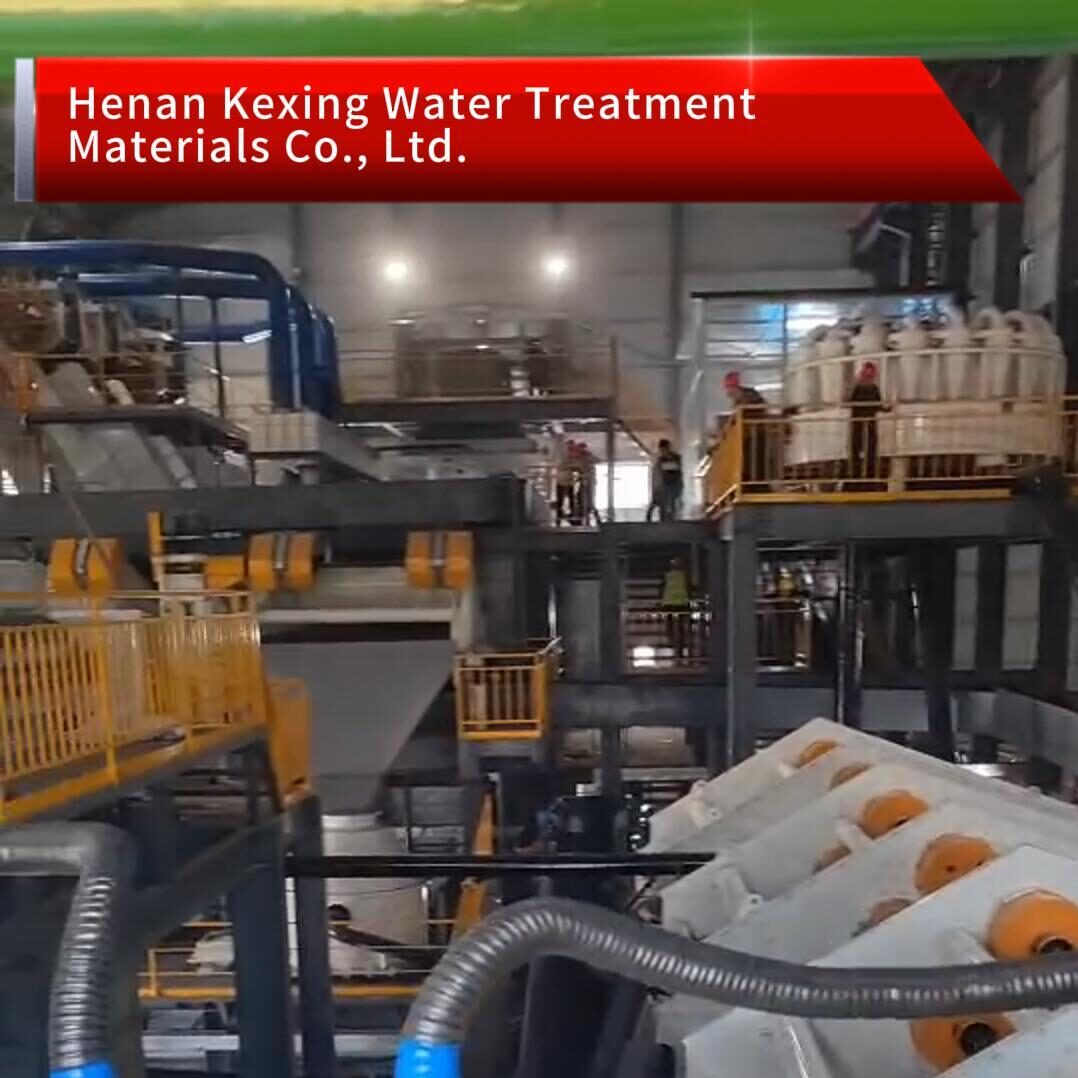

Executes Emergency On-site Optimization for New Client’s Flocculant Dosing System

Technical team adjusts polyacrylamide and polyaluminium chloride applications based on real-time water analysis

After purchasing a batch of crucial water treatment chemicals, a new customer urgently needed technical support. Within 4 hours of the first contact, our Chemical Application Response Team (CART) arrived at the factory in Inner Mongolia, equipped with mobile detection equipment.

Technical Intervention Sequence:

- On-site Diagnostic Protocol

- Conducted jar testing with client’s raw water samples

- Analyzed cation/anion balance impacting polyacrylamide (PAM) performance

- Measured baseline turbidity (12.3 NTU) and pH instability

- Precision Adjustment

Implemented real-time reagent optimization:

✓ Reduced polyaluminium chloride (PAC) dosage by 18%

✓ Modified PAM injection sequence from simultaneous to staggered feed

✓ Calibrated dosing pumps ±0.5% accuracy - Validation & Outcome

Post-intervention metrics confirmed:

▶ Floc formation time decreased 40% (T₉₀: 8min → 4.8min)

▶ Sludge volume index improved to 78 mL/g

▶ Production throughput increased 22%